Systems

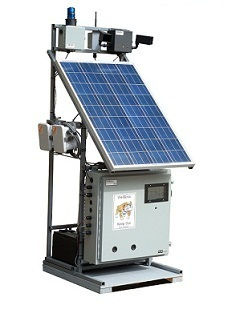

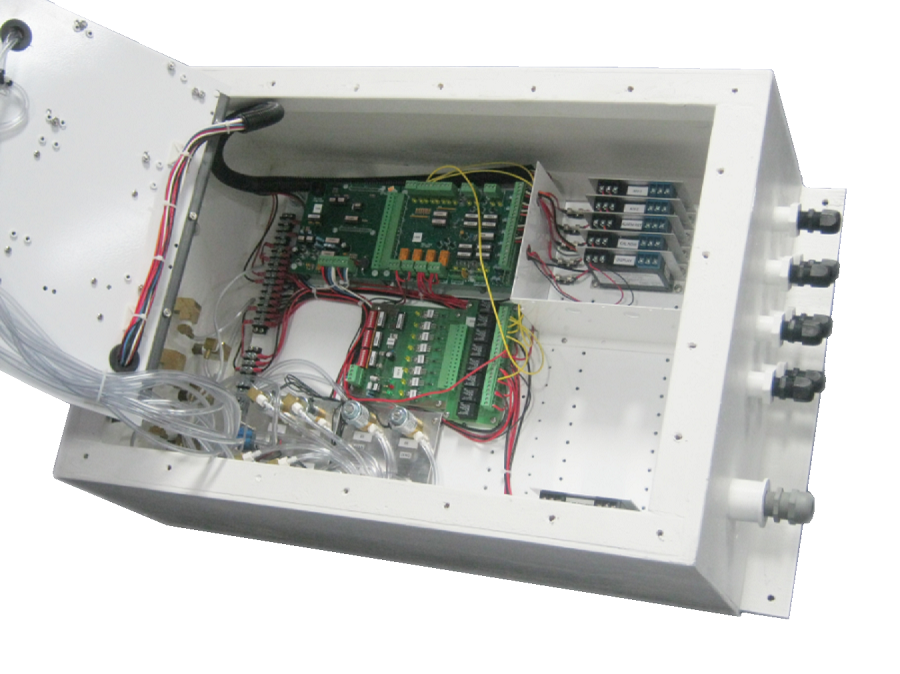

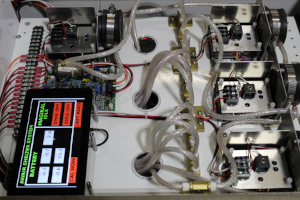

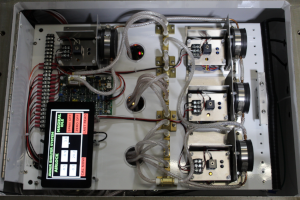

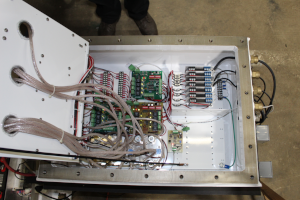

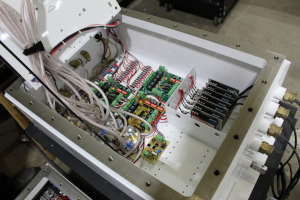

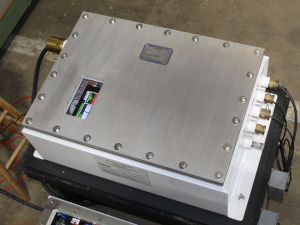

AwAir – Permissible Automatically Calibrating Gas Monitoring System - used mainly in mining applicationBe aware of your air, with AwAir™ ORDER NOW (Hover over the image to enlarge) Well, Rel-Tek has pioneered again, furthering technology for mine safety. This time, it’s an integrated gas monitoring system for an underground Refuge Alternative (RA)…aka, emergency shelter. For over two years Rel-Tek has worked to develop and perfect a gas monitoring system to satisfy the demanding RA air-monitoring requirements, per 30 CFR, Parts 7 and 75. This Part 18 approved system (18- A150009-0) is available for use in your shelter or as a stand alone system in Gob areas or other hazardous area underground. Conferring with MSHA for assessment of safety issues along the way, we now have an optimized air monitoring system that not only meets the requirements, but further enhances safety and assures precise sensor accuracy. We designed the “AwAir” trademark because it succinctly describes Rel-Tek systems that address the safety of miners inside the refuge, providing information to occupants on air quality in and around the living quarters. Basic SystemPhysically, AwAir comprises an explosion proof box, with sample-draw gas tubing entering through flame arrestors for continuously sampling the gas inside the living chamber, inside the air lock, and outside the RA. Gas sensors inside the XP housing analyze the gas streams for air quality. The air quality readings are viewed through a window on the enclosure lid, showing the amounts of oxygen, carbon monoxide, carbon dioxide and methane. Miners inside are alerted of any hazardous condition by visual and audible alarms. A hydrogen sensor and sample tube can be included for monitoring a battery compartment. An auxiliary relay is provided for controlling an external oxygen supply (by others.) A solid-state computer controls the gas sampling, monitoring processes, digital display and alarms. (click on the image to enlarge) An intrinsically safe battery maintains the system operation for at least the required 96 hours, i.e. the design life-support duration of an RA. Because the RA access doors are sealed and can be dormant for two years or more before use, the AwAir system is activated by the first person entering by pulling a lever. Then pushing the Cal-Now button initiates MagiKal, our fully automatic gas sensor calibration utility, assuring accurate gas readings. A over decade ago Rel-Tek developed its MagiKal automatic gas sensor calibration system. It is now used across the country, automatically calibrating large arrays of gas sensors on a computer-scheduled basis. Indeed, this same technology – involving integrated hardware and software – is a textbook transplant -- whereby safety is overwhelmingly enhanced, while manual on-going sensor maintenance is eliminated. The sensor complement includes CO, O2, CH4 and CO2 gas sensors, and one optional hydrogen sensor. They are all located on the top (hinged) layer within the XP enclosure. Sensor signals are linked to the PLC-Express (Platinum) solid state computer on the bottom layer of XP enclosure. Two MSHA-classified alarms announce low and high alarm conditions. An external push-button switch can silence the audible alarm. A window in the XP control box shows all sensor readings, sequenced on a backlit LCD display. Larger systems with additional sensors for smoke, temperature, humidity, barometric pressure and air velocity are pending. (click on the image to enlarge) LCD Display NomenclatureFirst Letter:O = Outside A = Airlock L = Living Area B = Battery Compartment Next 3 alphanumeric characters: Show the type of gas e.g. CO is Carbon Monoxide Next 4 digits, plus decimal point: Sensor Value in % or actual EU (Engineering Units) Safety philosophyThe major enclosure is MSHA-approved explosion proof, while all external electrical connections are intrinsically safe, the latter provided by a group of MSHA approved IS barriers. The battery pack is MSHA-approved IS, and is stowed in the utility compartment for easy external access. The two alarms have blinking amber lights and a soft-sounding bleeper, also MSHA approved IS. Switches are dry contacts, compatible with the attending barriers. Automatic Sensor CalibrationAutomatic calibration can be conducted anytime by simply pressing the Cal-Now button. NIST-certified cal-gases – zero gas and a composite span gas – are then introduced to the sensors. Computer adjustments are automatically applied for each sensor using 12-bit resolution (.0244% digitizing precision), far more accurate than would be possible manually. Calibration records are stored in non-volatile memory until updated. The two disposable tanks of calibration gas are housed in the RA utility compartment for accessibility from the outside, typically without breaking the RA seal. Tank pressures can be inspected externally, and if needed, replacement cal-gas tanks can be installed in minutes. Power ConsumptionThe AwAir system draws about 12 watts. The 12V battery pack, stowed in separate XP enclosure, continuous recharging, to assure at least the required 96-hour capacity. MSHA ApprovalA complete system approval application is on file with MSHA. Since most of the intrinsically safe sensors and XP boxes used are already approved, any additional testing and evaluation is minimal, and a full system approval is imminent. |

Images of Awair Gas Detection System (Click the images to enlarge):

Lets Get in Touch!

Your inquiries will promptly be answered.

Call us

412-3736700