New Products

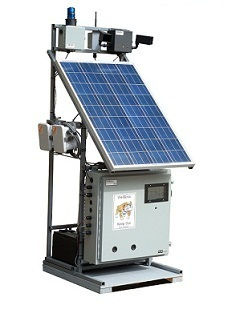

Spill SwitchORDER NOW Spillage Switch is designed to trip and shutdown the conveyor system when a predetermined amount of spillage is present to activate the switch (pressure plate). This helps to eliminate

Specification Sheet

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lets Get in Touch!

Your inquiries will promptly be answered.

Call us

412-3736700

buried head and tail pieces of the conveyor belt. Typical applications would include all bins, hoppers, belt heads, and tail pieces and anywhere spillage is a problem. Face hinged pressure plate toward belt (coal). Wire to the normally open contacts of switch and the pre-determined digital input of the controller (if applicable).

buried head and tail pieces of the conveyor belt. Typical applications would include all bins, hoppers, belt heads, and tail pieces and anywhere spillage is a problem. Face hinged pressure plate toward belt (coal). Wire to the normally open contacts of switch and the pre-determined digital input of the controller (if applicable).